Motor Protection with Load Monitors

When it comes to manufacturing, there are a variety of issues that can cause inefficiencies and defects in the production process. Equipment failure, setup and adjustments, idling and minor stops, reduced speed, and process defects can all contribute to reduced yield and increased costs. One important aspect of preventing these issues is ensuring the proper protection of motor-driven machines. These machines are often critical components of manufacturing processes and can be expensive to replace if they fail.

Therefore, it is essential to take steps to protect them from damage. There are several ways to protect motor-driven machines, including installing overload protection devices, ensuring proper lubrication and maintenance, and monitoring the machines for signs of wear or damage. By taking these precautions,

manufacturers can help ensure the reliability and longevity of their equipment and minimize the risk of process defects and reduced yield.

Motor driven machines that continue to operate during abnormal conditions caused by a jam or blockage will result in irreparable damage, not only to the motor continuing to drive the system but also to the machine itself. In the past the extent of damage to the machine has been understated compared to the damage to the motor itself regardless of whether a variable speed drive is being used or not. Motor management and control devices, or overloads can protect motors, but the question here lays with what is protecting your machine? In pump installations for example when there’s a jam or suction loss long before the thermal overloads trip, serious damage can be incurred by the machine as well as the motor. Reality here is any abnormal operating condition can have a detrimental effect on the life of the system. Dry pump, dead head, jammed impellers and even premature bearing wear can lead to motor and pump failure. To save upfront costs many motor driven systems are installed without any means to continually monitor operations. As a result, frequent inspections of the motor and the operation of the machine becomes a necessity for maintenance and repair.

If failure becomes apparent without warning it can mean irreparable damage to the machine and possibly the motor. These unforeseen issues can be eliminated with the use of simple but effective monitoring and control techniques to protect the motor driven systems. Adding a small cost to the installation will pay for itself a few times over the first time a fault is detected, and the machine or motor is saved.

This article will examine the importance of torque and power consumption by the motor, the proportionality between power and torque which are valuable feedback in many industrial applications.

To fully analyse a motor’s health, one must consider all aspects that can affect it under normal operational conditions. Incoming power quality is one area that is often overlooked, correct and safe operation of motors will depend on power conditions. As voltage levels alter during the day there can be imbalances. Raising voltage levels to decrease current and achieve the motors name plate ratings causes excessive heat, hence degrading the insulation. Harmonic distortion also affects the power quality, much of which is caused by variable frequency drives (VFD) and other facilities within the vicinity which go undetected most times.

Typically, during each start motors tend to draw six to ten times the rated current levels and with hot starts this is even more detrimental to the windings due to excessive heat generated causing insulation degradation. Besides normal operating data if voltage, current and torque level information was captured at motor start, it would be realised the amount of stress a motor is subjected to and hence as a result in many cases motors fail during this start up period.

During fluctuating loads and power condition problems rotors come under a tremendous amount of stress typically at startups. Monitoring these conditions are vitally important in determining the motors’ ability to continue operating. Losses in efficiency can be due to cracked or broken rotor bars which can cause a dramatic increase in thermal stress.

Load, % of load, horsepower demand, kilowatt usage, and power factor are all important elements that help to deduce the motors health. If motors are forced to carry out load demands above their capacity, this can cause the windings to run at unsafe temperature levels, even though the current is at nameplate current ratings. A Motor running above its nameplate horsepower rating can also suffer from higher torque demands putting greater stress on its rotor.

In the real-world motors are commonly oversized and occasionally undersized with both having their own cost implications. If oversized Initial cost, energy consumption and repair costs will be higher. Undersized perform poorly, suffer from higher losses, and will fail earlier. Some of these problems can be detected and corrected quickly by the sophisticated digital motor load monitors, which are designed and manufactured by UNIPOWER in Denmark. They have a broad range of quality products for specific and general applications aimed at motor driven systems therefore, chances are Unipower has a solution.

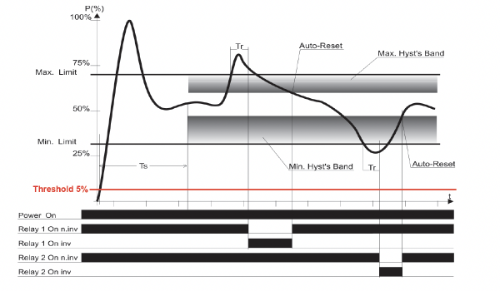

A load monitor from UNIPOWER measures the load on the motor electronically. The motor is acting as its sensor to detect the state of the equipment the motor is driving. This is primarily to protect the machine from damage but can also protect the motor. In an abnormal running condition, the Load Monitor measures the load drawn by the motor and compares it to what it was when normal.

The most common use would be pump dry run detection. As discussed earlier many pumps cannot be allowed to dry run, particularly in Petrochemical, Agrochemical and Pharmaceutical industries where hazardous chemicals are being pumped. In the water industries dry running and dead heading due to impeller being jammed will also show an abnormal motor load.

UNIPOWER Load monitors calculate Watts/Kilo Watts (kW) which is the only electrical measurement of work that is linear with and proportional to load, using the formula:

P = √3 × I × V × COSꝋ.

Many products are claimed to achieve the same by measuring the current. This is particularly a problem when the motor is over sized which does happen often as discussed earlier. In such cases the motor will never reach its rated load as the motor is too large for the job and hence will operate where current is a flat line, so you cannot measure current for variations in work being done by the motor.

Phase angle detection was another way round this however, with the advancement of technology and the increased efficiency of newer motors, phase angle detection is not a reliable alternative for measuring work done by the motor.

Supervision and control are uniquely offered by the UNIPOWER family of Motor Load Monitors, replacing friction clutches, ball detent clutches, shear pins, tacho controllers etc. Typical applications include belt and screw conveyors, elevators, fans, pumps, filtration screens, macerators, etc.

UNIPOWER product designs recognise that in order to use power consumption as an indirect torque measurement the power must be measured by the use of formula mentioned. Measurement must be fast and accurate, reaction time must be short, measurements must be valid for none sine-shaped currents i.e. frequency inverters generating very high and short current peaks (crest factor up to 10) and include support functions such as start timer, reaction delay timer, peak detectors for max/min load, and shock Load monitoring dP/dt with voltage spike compensation dU/dt.

Available exclusively from UNIPOWER UK Ltd T/A Charter Controls.

Protecting motor and driven load: let’s torque sense

The UNIPOWER HPL500 digital motor load monitor from Charter Controls protects machinery by monitoring the electrical power of the motor driving it.

Motor power is the only purely electronic measurement of motor load, which is linear with and proportional to, the mechanical load on the motor. An alternative is torque measurement; however, this requires a speed input from an electro-mechanical sensor and can be significantly more expensive.

Motor current is essentially flat line from idle load to 50-60 percent of full motor load and fluctuates with site voltage. Above 50-60 percent of full motor load, depending on the motor efficiency, motor current increases at an almost exponential rate with an increase in mechanical load. It is nigh on impossible to establish a reliable and repeatable trip point on an exponential curve. Take this example for a motor rated 10A full load current:

Using the power equation: 1.73 x I x V x Cos f (I=current; V= voltage)

At idling: 1.73 x 5 x 415 x 0.15 = 538W

At approximately 50-60 percent load: 1.73 x 5 x 415 x 0.5 = 1,794.8W

At approximately 100 percent load: 1.73 x 10 x 415 x 0.8 = 5,743.6W

In the first two examples the current has not changed: Cos f changes and the power increases correspondingly. In the third example the motor is running at its rated current and approximate motor plate Cos f. Modern motors can run at Cos f of between 0.85 and 0.9. This exacerbates the problem because the current increase comes later in the motor's power band.

Over-Sizing Motors

Current may be suitable for a crude motor load application until you consider the common practice of over-sizing motors. In the article I referred to above, it was stated that up to 80 percent of pump motors could be oversized by as much as 10 to 15 percent. Engineers may be doing this to be ‘on the safe side’ or may be incorporating a ‘non-overloading characteristic’.

If a motor is over-sized for the task, it may never reach the 50-60 percent of load at which its current starts to increase; and you won’t know until the motor has already done the damage. Motor load monitors are the only electronic devices suitable to monitor mechanical systems and installations when a mechanical problem occurs.

Mechanical devices such as clutches, ball-detent torque limiters and shear pins are often installed externally and open to the elements. They require regular inspection and maintenance to give constant and reliable protection. Motor load monitors, on the other hand, are located in the motor control panel and are truly ‘fit-and-forget’ devices.