Introducing the WECON V-Box

Embracing the Future of Manufacturing: How Data-Driven Technologies Are Shaping Industry Standards

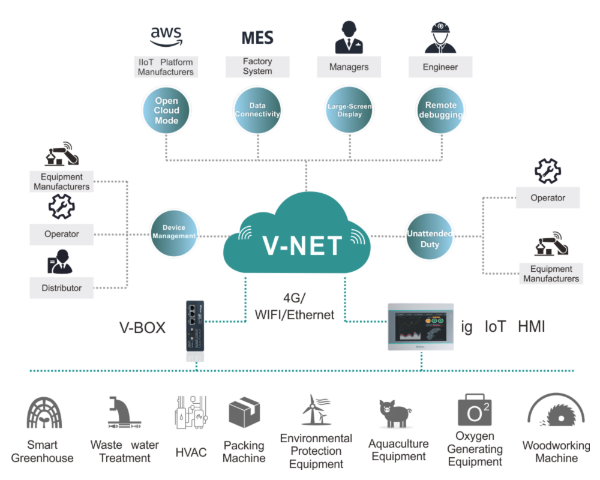

In today's rapidly evolving industrial landscape, the shift towards data-driven manufacturing is not just a trend but a crucial strategy for staying competitive. The integration of real-time data collection, proactive maintenance, and strategic planning into manufacturing processes is transforming how industries operate, enhancing efficiency and reducing downtime. Among the innovative solutions leading this transformation is the WECON VBOX, supported by V-NET technology, which together provide a robust framework for optimising manufacturing operations.

The Role of Real-Time Monitoring and Control

Real-time monitoring and control are at the heart of modern manufacturing, with systems like the WECON VBOX playing a pivotal role. By continuously collecting and analysing data from machine components via sensors, the WECON VBOX ensures that machinery operates within optimal parameters. This constant vigilance helps in immediately identifying and correcting deviations, which not only prevents equipment damage but also ensures consistent product quality.

For instance, by monitoring critical parameters such as temperature, pressure, and speed, the WECON VBOX can detect anomalies and automatically adjust processes or alert operators. This capability not only supports proactive maintenance but also prevents costly downtime, making it an indispensable tool in the manufacturing toolkit.

Enhancing Process Automation

Automation is a key benefit of the WECON VBOX system, allowing for seamless control of machinery through programmable logic. This automation extends from simple tasks, such as starting and stopping machines, to more complex adjustments like modifying operational speeds and switching between modes—all without human intervention. The result is a significant increase in efficiency, reduction of human error, and lower operational costs, culminating in higher production throughput and better quality control.

Driving Efficiency and Energy Savings

Energy consumption is a major cost factor in manufacturing. The WECON VBOX system addresses this by optimising machine operations and energy usage, ensuring that machines run only as needed and always at peak efficiency. This not only helps in cutting down energy costs but also contributes to sustainability goals, a growing concern in modern manufacturing environments.

Remote Management and Predictive Maintenance

The flexibility of the WECON VBOX is further enhanced by V-NET, which facilitates remote management and diagnostics. This setup allows operators to monitor and control machinery from central locations or remotely, reducing the need for on-site personnel and enabling quick responses to any arising issues. Moreover, predictive maintenance capabilities allow for the analysis of operational data to forecast potential failures before they occur. This proactive approach minimises unexpected downtime, extends machine lifespan, and optimises overall machine performance.

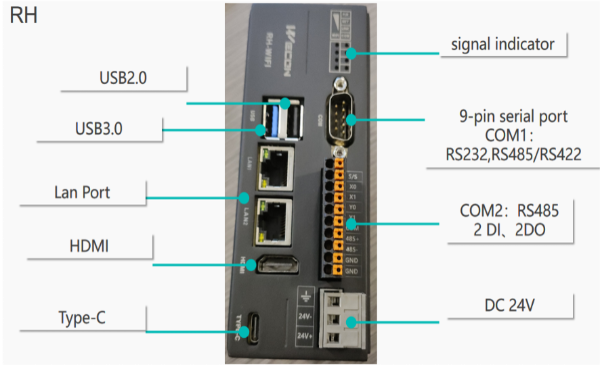

The WECON VBOX can be accessed via iOS or Android apps, and different models are available, from small to large, capable of connecting through 4G, Ethernet, or WiFi, making it one of the most cost-efficient products currently available in the industry, available from Charter Controls.

Scalability, Compliance, and Reporting

As manufacturing demands grow and technologies evolve, the modular design of the WECON VBOX and the scalability of V-NET prove invaluable. This flexibility allows manufacturers to expand or modify their systems without extensive overhauls, providing a future-proof solution to technological advancements. Additionally, the WECON VBOX system simplifies compliance and reporting, automating the collection and documentation of operational data to meet industry regulations and standards.

Return on Investment

Implementing the WECON VBOX and V-NET systems represents a significant upfront investment in technology. However, the return on this investment is quickly realised through enhanced diagnostic capabilities, reduced downtime, energy savings, and improved overall efficiency. The data-driven approach not only streamlines maintenance operations but also provides strategic insights that can lead to better decision-making and increased productivity.

Conclusion

In conclusion, as the industry moves towards more integrated and intelligent manufacturing systems, technologies like WECON VBOX and V-NET stand out as essential tools. They not only meet the current demands of data-driven manufacturing but also anticipate future needs, ensuring that businesses remain at the forefront of industry developments. Embracing these technologies means not just keeping up with the times but setting the pace for innovation in manufacturing.

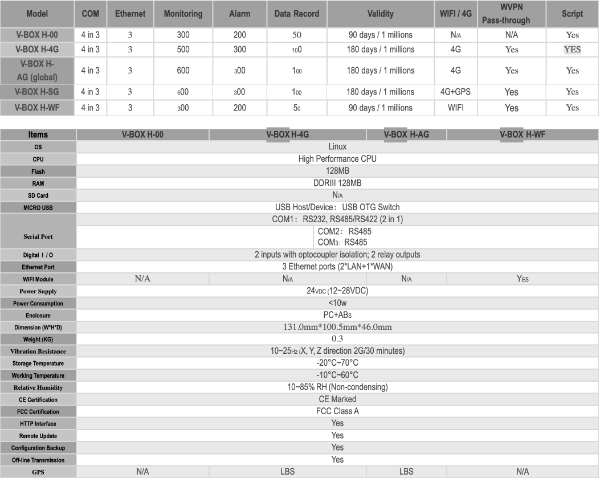

V-Box H Series Available Models

V-Box H-AG Specifications

| Feature |

Specification |

| Model |

V-Box H-AG |

| COM |

4 in 3 |

| Ethernet |

3 |

| Monitoring |

600 |

| Alarm |

300 |

| Data Record |

100 |

| Validity |

180 days/1 million |

| WIFI/4G |

4G |

| WVPN Pass-through |

Yes |

| Script |

Yes |

| OS |

Linux |

| CPU |

High Performance CPU |

| Flash |

128MB |

| RAM |

DDRIII 128MB |

| SD Card |

N/A |

| MICRO USB |

USB Host/Device: USB OTG Switch |

| Serial Ports |

COM1: RS232, RS485/RS422 (2 in 1)

COM2: RS485

COM3: RS485 |

| Digital I/O |

2 inputs with optocoupler isolation; 2 relay outputs |

| Ethernet Port |

3 Ethernet ports (2*LAN+1*WAN) |

| WIFI Module |

Yes |

| Power Supply |

24VDC (12~28VDC) |

| Power Consumption |

<10W |

| Enclosure |

PC+ABS |

| Dimension (W*H*D) |

131.0mm*100.5mm*46.0mm |

| Weight (KG) |

0.3 |

| Vibration Resistance |

10~25Hz (X, Y, Z direction 2G/30 minutes) |

| Storage Temperature |

-20°C~70°C |

| Working Temperature |

-10°C~60°C |

| Relative Humidity |

10~85% RH (Non-condensing) |

| CE Certification |

CE Marked |

| FCC Certification |

FCC Class A |

| HTTP Interface |

Yes |

| Remote Update |

Yes |

| Configuration Backup |

Yes |

| Off-line Transmission |

Yes |

| GPS |

Yes |

VIDEOS

WECON V-Box Introductions

WECON V-Box Product Training